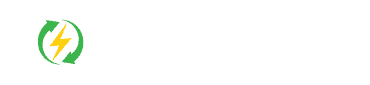

In the world of modern technology, high efficiency converters are pivotal in enhancing the performance and energy efficiency of various machinery and equipment.

The top options are the series output and parallel input/series output designs. They split the input current, boosting conversion efficiency.

This is ideal for high-powered devices, as it maximizes performance and reduces energy costs. The transformer-less DC-DC converter is also a unique option.

The design removes the need for a transformer, reducing components and costs. We will explore the benefits of efficient converters and their impact on various applications.

Understanding High Efficiency Converters

High efficiency converters are crucial in power electronics, converting input power into output power while minimizing energy losses. They are widely used in power supplies, electric vehicles, renewable energy systems, telecommunications, and more.

High efficiency converters transform electrical energy to enhance energy utilization in modern technologies. They convert electricity with maximum efficiency in power supplies, reducing waste and optimizing performance.

This is crucial for portable electronic devices, as it extends battery life and reduces environmental impact.

Working Principle of High Efficiency Converters

High efficiency converters convert electrical energy, minimizing power wastage. They convert AC to DC, DC to AC, DC to DC, or AC to AC as needed.

To achieve high efficiency, converters use advanced electronic components and techniques. Semiconductor devices like diodes, transistors, and switches play a crucial role in controlling electrical currents.

These devices enable precise manipulation of current flow, facilitating the conversion process by allowing it to flow in desired directions and blocking it in others.

4 Types of High Efficiency Converters

There are different types of high efficiency converters for specific power conversion needs.

These converters are important in power electronics for a variety of applications. Here are some common types of high efficiency catalytic converter.

- Buck Converter: Also called step-down converter, it efficiently reduces voltage levels by toggling the input voltage at high frequency. This pulse-like waveform is then smoothed out to produce a lower output voltage. Used for portable electronic devices and microprocessor voltage regulation.

- Boost Converter: The Boost converter boosts the output voltage above the input voltage. It stores energy in an inductor and releases it with increased voltage. It is used in battery-powered systems when higher voltage is needed.

- Buck-Boost Converter: The Buck-Boost converter combines the Buck and Boost converters, regulating output voltage higher or lower than input voltage. It is ideal for applications needing step-up and step-down voltage conversions, like battery charging and adjustable power supplies.

- Isolated Converter: Isolated converters have electrical isolation between input and output, making them ideal for applications requiring galvanic separation, safety, or noise immunity. They use transformers or optocouplers to transfer energy across the isolation barrier. They are commonly used in telecommunications, medical equipment, and power systems.

The Benefits of High Efficiency Converters

High efficiency converters are vital in modern power electronics, offering numerous benefits beyond power conversion. Key advantages of these converters include:

- Substantial Reduction in Power Loss: High efficiency converters utilize advanced technology to minimize power losses during the conversion process. This means a greater proportion of input energy is transformed into the desired output, resulting in less wasted energy. This improvement leads to enhanced cost savings, better performance, and a reduced environmental impact.

- Enhanced System Reliability and Extended Lifespan: By reducing the amount of heat generated, high efficiency converters contribute to increased system reliability. Less heat dissipation translates to cooler operating temperatures, which lowers thermal stress on components. This results in a longer operating life for devices and reduces maintenance costs.

- Energy Conservation and Environmental Benefits: These converters are pivotal in conserving energy by minimizing power losses during conversion. The increased effectiveness in using electrical energy lowers the overall demand for energy in power generation and distribution. This approach is sustainable and environmentally friendly.

- Lower Operational Costs: With reduced power losses and heightened energy efficiency, high efficiency converters decrease operational costs in various applications, including power supplies, electric vehicles, and renewable energy systems. Their cost-effectiveness makes them a popular choice across different industries.

The Potential of High Efficiency Converters

High-efficiency converters, characterized by high switching frequencies and complex designs, are costly but offer significant efficiency advantages. Key findings from a study include:

- Improved switch-up behavior in 3.3 kV SiC-Device modules, with voltage switching steps reduced from 1100 V to 500 V.

- The importance of selecting the right resistance level, as efficiency varies inversely with power source resistance.

- Introduction of a new non-isolated interleaved dc/dc buck converter, combining voltage multiplier cell and interleaved techniques. This design reduces voltage stress and increases efficiency using lower-rated diodes and MOSFETs.

- Successful laboratory testing of the prototype at 40 kHz, demonstrating its potential for commercialization.

The study emphasizes the balance between source resistance and efficiency in DC-DC converters, highlighting that lower resistance leads to higher efficiency.

Despite the high efficiency, practical system limits might require other solutions.

High-Efficiency DC-DC Converters

The proposed high-efficiency DC-DC converter significantly surpasses previous models in performance, delivering 248 W of output power with an impressive 97.4% efficiency. Its key advantages include:

- High Efficiency and Power: Capable of converting power at a high frequency, leading to substantial energy savings.

- Compact Size: More compact than linear regulators, despite a decrease in efficiency with increased frequency.

- Versatility: Suitable for a wide range of applications, especially in power electronics where space is a premium.

- Improved Design: Incorporates advancements like reduced size and height, lower power consumption, and better electromagnetic interference management, as exemplified by Murata's lineup of buck regulators.

- Innovative Features: The transformer-free design is tailored for renewable energy applications, offering high voltage gain and efficient voltage step-up/step-down operations with a single power switch. This reduces switching losses and voltage stress.

- Self-Tuning Capability: Optimizes performance for various operating conditions, fully utilizing the switching cycle.

Despite these benefits, DC-DC converters have downsides like noise generation and complexity, making them more suitable for situations where reducing power consumption is critical.

The high-voltage-gain feature of the converter makes it ideal for transformer-less applications, providing a non-pulsating input current and the ability to combine into a single-stage converter.

Understanding the Functionality and Optimization of Power Conversion

A high-efficiency load converter is used to convert the DC output current to direct current.

This device is based on the principle of discontinuous conduction, where the resistor current ramps to zero before each clock cycle.

Hence, a load comparator is needed to turn off the low side MOSFET before the inductor current becomes negative, preventing additional losses. The converter must also be able to detect the rising edge of the first clock cycle, and then switch to the external clock.

If there are no rising edges detected on the SYNC pin for four clock cycles, a switchover will be initiated. In this case, the maximum delay time is eight us.

The output capacitors used in the converter determine the ripple in the output voltage. For the lowest output voltage ripple, the output capacitor should have a very small ESR value.

The output capacitor value can be as small as X7R or X5R. As the output capacitor size is limited, the converter will operate in Power Save Mode at low load currents. The output capacitor will also add to the overall quiescent current.

Transformer-less DC-DC Converters

DC-DC converters come in two types: isolated with transformers and non-isolated. This article focuses on transformer-less converters, which use switched-capacitor and boost converter technologies to achieve higher voltage gain.

They have benefits such as moderate duty cycles, non-pulsating input current, and low input current ripple.

DC-DC converters are popular for automotive and industrial use due to their efficiency and power density.

However, managing high indirect power is a challenge. An emerging alternative is DCX converters, which are efficient and have a boost inductor for increased voltage gain.

Transformer-less converters are often more efficient and reliable than transformer-based ones, reaching up to 94% peak efficiency. Yet, the efficiency of DC-DC converters can be affected by input resistance.

High source resistance can cause efficiency losses and bistability, affecting system performance.

Conclusion

As I reflect on the wealth of information about high efficiency converters and their various types and applications, I am truly impressed by the advancements in power electronics and their significant impact on energy efficiency and sustainability.

Learning about the series output and parallel input/series output topology, the transformer-less DC-DC converter, and other innovative designs has given me a deeper understanding of how these devices play a crucial role in optimizing power conversion.

It is evident that high efficiency converters offer a plethora of benefits to companies like ours, especially those operating high-powered machinery and equipment.

The potential for reduced energy costs, enhanced system reliability, and extended lifespan of electronic components is particularly appealing.

Embracing these advanced converters aligns perfectly with our company's commitment to achieving energy efficiency without compromising on performance.

Sources