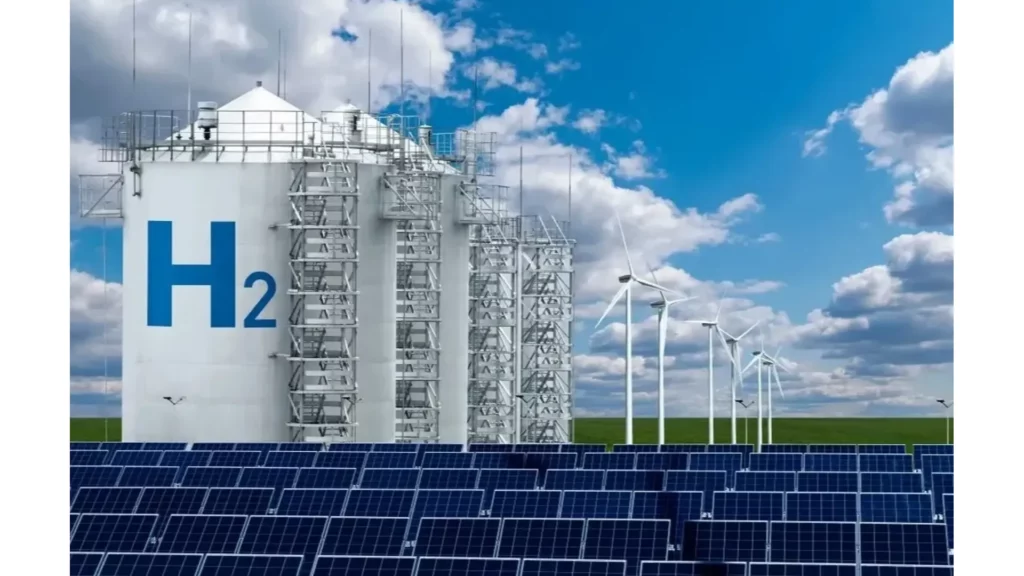

Green Hydrogen Production Plant in Patagonia

The race towards a sustainable future is on, with green hydrogen at the forefront of transforming the world's energy systems.

From the remote regions of Patagonia to the innovation hubs of New Jersey, groundbreaking projects are paving the way for a carbon-neutral future.

Here's an in-depth exploration of these initiatives and their role in the global energy transition.

Chile's Patagonian Wind: A Catalyst for Change

In Chile's Patagonia, the Enel Group is not just building a green hydrogen production plant; it's pioneering a movement.

The project taps into the region's vast renewable resources, leveraging the fierce Patagonian winds to produce hydrogen in an environmentally friendly manner.

- Strategic Importance: Positioned in Punta Arenas, this initiative aims to transform the area into a global green hydrogen hub, showcasing the potential of renewable resources in even the most challenging climates.

- Community Engagement: The project is a beacon of hope for local development, promising new jobs and a sustainable economic model based on clean energy production.

Enegix in Brazil: Redefining Energy Paradigms

Brazil's Enegix is setting a bold vision with its green hydrogen plant in Pacem.

This venture is not merely about energy production; it's about reshaping the global energy landscape.

- Broad Impact: By aiming to displace traditional oil and coal, Enegix's initiative represents a significant leap toward reducing global carbon emissions.

- Innovative Technology: The focus extends beyond hydrogen production to developing a comprehensive green hydrogen infrastructure, setting a precedent for future projects worldwide.

Expanding Horizons:

- Global Collaborations: Partnerships, like the one with Oman, underscore the international dimension of the green hydrogen movement, highlighting the interconnectedness of our energy futures.

New Jersey's Evolution: From Natural Gas to Green Hydrogen

New Jersey Resources Corp's transformation is a testament to the evolving energy sector's adaptability.

By focusing on green hydrogen, NJRC is leading by example, demonstrating how traditional energy companies can pivot towards sustainability.

- Historical Shifts: The strategic decision to divest from non-core assets and invest in clean energy ventures marks a significant shift in NJRC's operational focus, aligning with global sustainability goals.

- Future-Proofing: Through its commitment to clean energy, NJRC is not just adapting to the present but future-proofing its operations against the backdrop of a rapidly changing energy landscape.

SGH2 Lancaster Plant: Revolutionizing Waste-to-Energy

SGH2's project in Lancaster, California, represents a groundbreaking approach to green hydrogen production, utilizing waste as a primary feedstock.

This innovative method not only produces clean energy but also addresses the critical issue of waste management.

- Technological Marvel: The gasification process that converts waste into hydrogen is a game-changer, offering a dual solution to energy and waste challenges.

- Economic and Environmental Synergy: The project's ability to save on landfill costs while producing green hydrogen exemplifies the synergy between economic benefits and environmental sustainability.

FPL Cavendish NextGen Hydrogen Hub: Florida's Clean Energy Milestone

The FPL Cavendish project is a pioneering venture in the U.S., showcasing the practical applications of green hydrogen in enhancing the existing energy infrastructure.

- Solar Synergy: Leveraging Florida's abundant solar resources to produce green hydrogen, the project highlights the potential of integrating renewable energy sources with green hydrogen production.

- Innovation and Scalability: The use of advanced electrolyzer technology points to the scalability of green hydrogen projects, offering insights into how similar initiatives can be replicated globally.

Air Products: Setting a Global Green Hydrogen Standard

Air Products' venture into green hydrogen production in Saudi Arabia is a landmark project with global implications.

It represents a significant step towards the commercialization and global adoption of green hydrogen.

- Strategic Partnerships: Collaborations with major mobility and energy companies reflect the broad, cross-sectoral interest in green hydrogen as a versatile energy carrier.

- Pioneering Market: The project's location in Saudi Arabia, a country synonymous with oil production, signifies the shifting energy paradigms and the Middle East's role in the green hydrogen economy.

The Broader Context: Green Hydrogen in the Global Energy Transition

The transition to green hydrogen is about more than reducing carbon emissions; it's about reimagining the global energy architecture.

These projects illustrate the diverse applications of green hydrogen, from decarbonizing heavy transport and industry to providing flexible energy storage and clean power generation.

Global Implications:

- Economic Revitalization: Beyond environmental benefits, green hydrogen projects are catalysts for economic development, offering new industries and job opportunities.

- Energy Security: By diversifying energy sources, countries can enhance their energy security, reducing reliance on fossil fuel imports and mitigating geopolitical risks.

- Innovation Ecosystems: The push for green hydrogen is driving technological innovations, fostering ecosystems where startups and established companies collaborate on developing new energy solutions.

Conclusion: A Unified Vision for a Sustainable Future

The global momentum towards green hydrogen underscores a unified vision for a sustainable, resilient, and equitable energy future.

From Patagonia's winds to the innovation labs of New Jersey, the journey toward green hydrogen is not just about transitioning to cleaner energy sources; it's about building a new foundation for global prosperity and environmental stewardship.

As we look ahead, the path is clear: embracing green hydrogen is imperative for achieving our collective environmental goals and paving the way for a sustainable future.

Through international collaboration, technological innovation, and strategic investments, we can turn the vision of a green hydrogen-powered world into a reality.

Photo Credit: Seetao

Source:

Feasibility analysis of green hydrogen production from oceanic energy