Biomass As a Renewable Energy Source

Biomass energy, derived from the organic materials of crops and animals, represents a pivotal shift towards renewable resources in our global energy portfolio.

This form of energy not only reduces our dependence on fossil fuels but also offers a pathway to mitigate climate change, enhance energy security, and foster sustainable development.

This article explores the multifaceted world of biomass energy, its diverse sources, applications, and the profound impact it can have on our planet and society.

The Essence of Biomass Energy

Biomass energy, at its core, is the process of converting organic material into electricity, heat, and fuels.

Unlike non-renewable fossil fuels, biomass resources replenish over time, making them a sustainable choice for the future.

The significance of biomass in today's energy mix cannot be overstated, as it provides a renewable alternative that contributes to reducing greenhouse gas emissions and combating global warming.

6 Key Sources of Biomass Energy

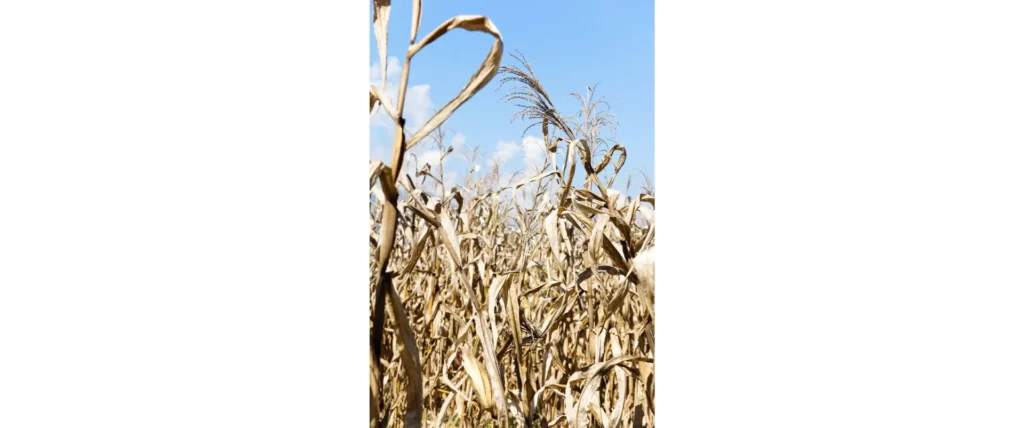

1. Crop Residues: The Agricultural Goldmine

- Wider Applications: Beyond their traditional uses, crop residues are increasingly recognized for their role in producing bioenergy. They contribute to making biofuels, generating electricity, and even manufacturing biodegradable products.

- Factors Influencing Availability: The sustainability and availability of crop residues are influenced by agricultural practices, seasonal variations, and regional differences. Innovative farming techniques and crop management can enhance residue yield for bioenergy without compromising soil health.

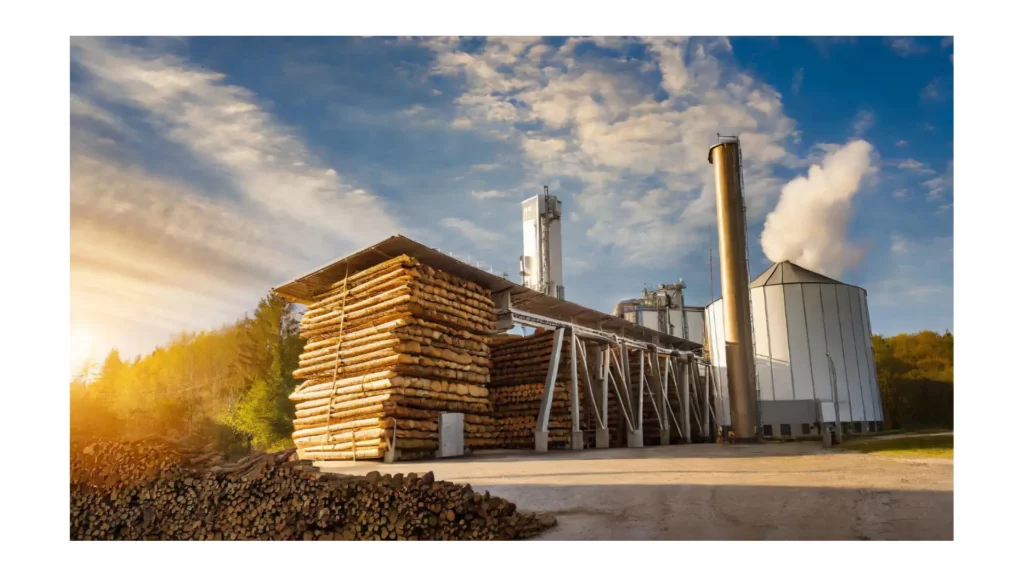

2. Wood: The Timeless Energy Resource

- Sustainability Concerns and Solutions: While wood is a renewable resource, its sustainability is contingent on responsible forestry practices that ensure regrowth and biodiversity. Modern sustainable forestry practices, coupled with advanced wood energy conversion technologies, can minimize environmental impacts.

- Community and Economic Benefits: Locally sourced wood energy supports rural economies, reduces transportation emissions, and fosters energy independence. Community-based wood energy projects exemplify how this biomass source can be both sustainable and socially beneficial.

3. Sawdust: Turning Waste into Energy

- Innovations in Utilization: Recent technological advancements have transformed sawdust from a waste product into a valuable resource for bioenergy. Through processes like pelletization and gasification, sawdust is converted into a clean, efficient fuel.

- Economic Viability: The economic model for sawdust-to-energy conversion is strengthened by reducing waste disposal costs and generating income from a by-product of wood processing.

4. Chicken Litter: An Unlikely Energy Hero

- Waste to Wealth: The conversion of chicken litter into energy is a prime example of turning waste challenges into economic opportunities. This process not only provides a renewable energy source but also addresses environmental concerns related to waste management.

- Technological Breakthroughs: Advances in conversion technologies have made it possible to efficiently extract energy from chicken litter, offering a template for other agricultural waste streams.

5. Forest Residues: The Untapped Potential

- Integrated Management Approaches: Effective management of forest residues for energy production requires integrated approaches that balance energy production with ecosystem health and forest regeneration.

- Case Studies of Success: Examples from Scandinavia and North America illustrate how forest residues can be sustainably harvested and converted into energy, contributing to regional energy needs while maintaining forest health.

6. Algae: The Future of Liquid Gold

- Cutting-Edge Research: Ongoing research into algae cultivation and processing is unlocking its potential as a biofuel source. Algae-based biofuels, such as biodiesel and bioethanol, are emerging as competitive alternatives to conventional fuels.

- Environmental Advantages: Algae cultivation has a lower environmental footprint compared to traditional biofuel crops, requiring less land and fresh water. Its ability to absorb carbon dioxide also contributes to greenhouse gas reduction efforts.

Learn more in our post about the pros of biomass energy.

The Environmental and Economic Landscape

Environmental Benefits

- Biodiversity Preservation: Sustainable biomass production practices contribute to preserving habitats and biodiversity, especially when compared to the extensive land use changes associated with fossil fuel extraction.

- Soil and Water Conservation: Biomass crops and residue management can improve soil health and water quality, enhancing agricultural sustainability.

Economic Impacts

- Job Creation and Rural Development: Biomass energy projects can stimulate job creation in rural areas, promoting economic development and revitalization.

- Energy Diversification: Incorporating biomass into the energy mix reduces reliance on imported fuels, enhancing national energy security and stability.

Navigating Challenges and Seizing Opportunities

- Balancing Economics and Ecology: The key to biomass energy's success lies in balancing economic viability with ecological sustainability, ensuring that biomass use does not outpace resource regeneration.

- Policy Frameworks and Incentives: Effective policies and incentives are critical to encouraging investment in biomass energy, from research and development to large-scale implementation.

- Community Engagement and Education: Engaging communities and educating the public about the benefits and sustainable practices of biomass energy are essential for gaining widespread acceptance and support.

Envisioning the Future: Biomass and Beyond

As we stand at the crossroads of energy transition, biomass energy offers a beacon of sustainability and resilience.

By embracing innovative technologies, fostering sustainable practices, and cultivating a supportive policy environment, biomass can significantly contribute to a cleaner, greener, and more sustainable energy future.

The journey from organic matter to renewable energy encapsulates the essence of human ingenuity and nature's bounty, underscoring the potential of biomass to power our world while preserving it for future generations.

Source: