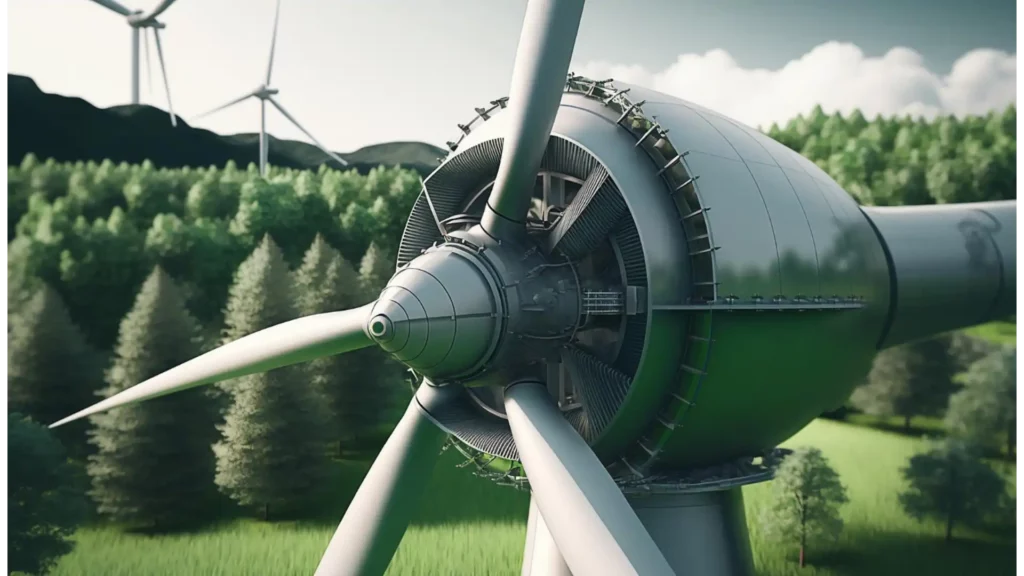

In the quest for sustainable and renewable energy sources, wind energy has emerged as a pivotal player in the global energy market.

Central to the efficiency and functionality of wind turbines is the wind energy gearbox, a critical component that significantly influences the performance and reliability of wind energy systems.

This comprehensive guide delves into the intricacies of the wind energy gearbox, exploring its design, operation, maintenance, and the latest technological advancements aimed at maximizing wind energy production.

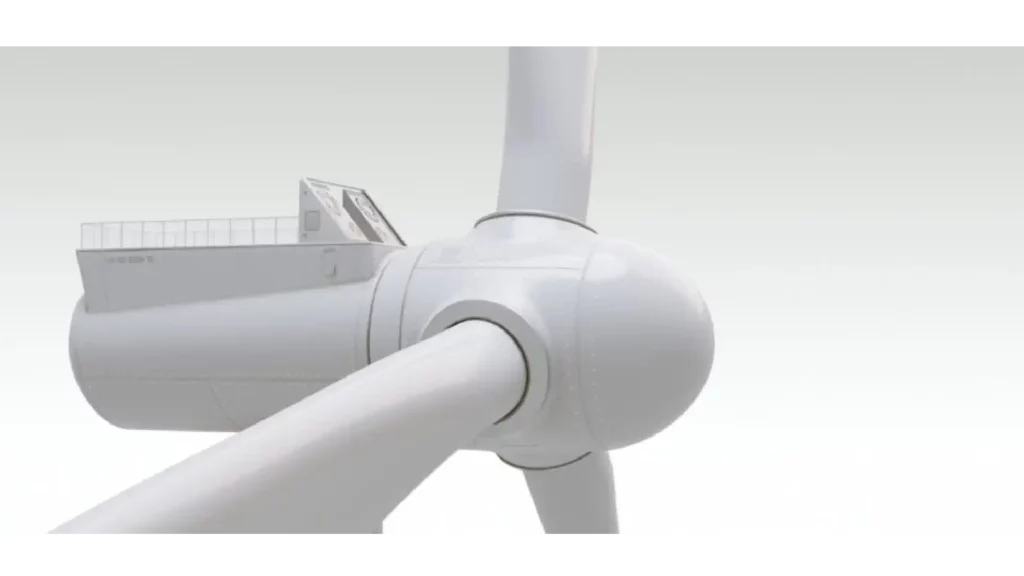

The Role of the Gearbox in Wind Energy Production

The wind energy gearbox serves as the heart of a wind turbine, playing an essential role in converting the kinetic energy from the wind into electrical energy that powers our homes and industries.

It does this by increasing the rotational speed of the turbine's slow-moving blades to a speed that the generator can use to produce electricity efficiently.

How Does a Wind Energy Gearbox Work?

A wind energy gearbox is a crucial component in a wind turbine, designed to convert the slow rotational speed of the turbine's rotor blades into a higher speed suitable for electricity generation.

It achieves this through a series of gears that step up the rotation speed, enabling the attached generator to produce electricity efficiently. The gearbox consists of various gear types, such as spur, helical, and planetary, along with bearings that ensure smooth operation with minimal friction.

This system is essential for the effective transfer of kinetic energy from wind to electrical power, highlighting the gearbox's key role in enhancing the efficiency and reliability of wind energy production.

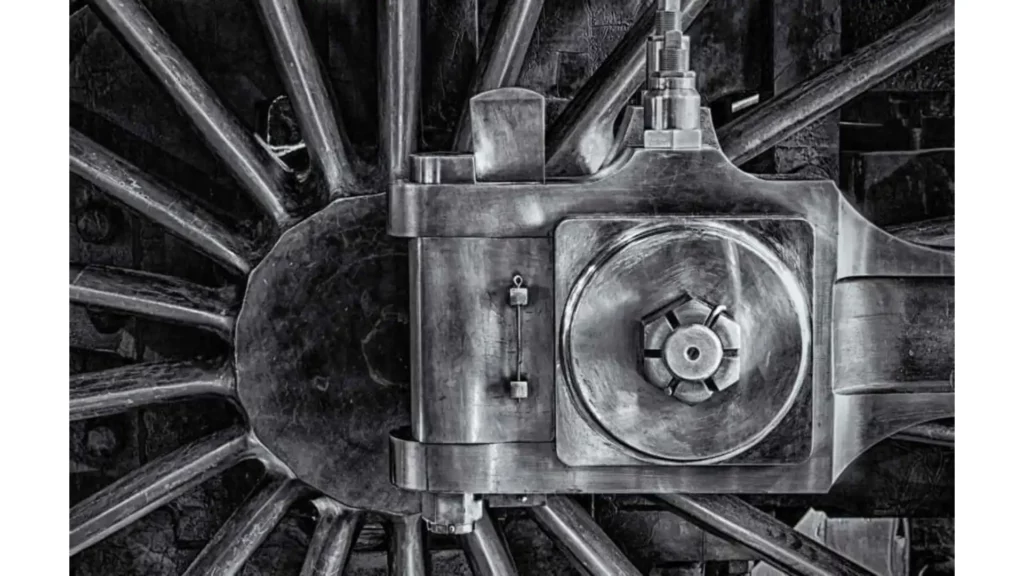

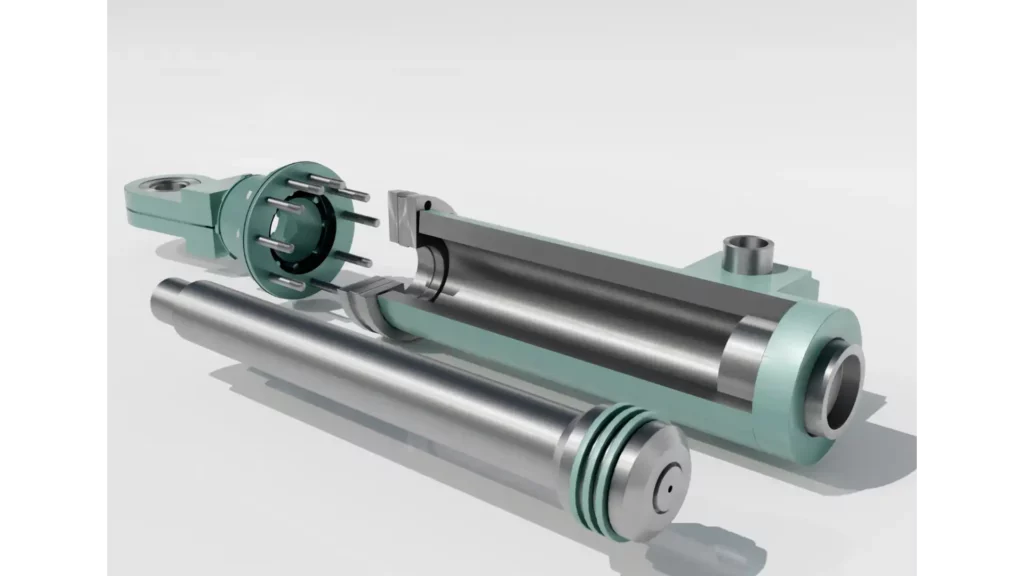

Key Components of a Wind Energy Gearbox

Understanding the components of a wind energy gearbox is crucial for grasping how it optimizes wind energy conversion. These components include:

- Input Shaft

The wind energy conversion process starts with the input shaft linked to the rotor blades, receiving rotational energy from the wind. Initially, the blades move slowly against the wind, resulting in a slow rotational speed.

- Gear Sets

The gearbox's essential component is its gear sets, which efficiently increase rotational speed from input to electricity generation.

Multiple stages of gears, like spur, helical, and planetary, are chosen for their durability and efficiency. Gear ratios are calculated to match the generator's needs, resulting in a significant speed increase.

- Bearings

Bearings are crucial for gear sets as they help in smooth rotation, reducing friction and wear for efficient operation and durability. They handle heavy loads and absorb operational stresses to maintain speed-increasing function without excessive heat or energy loss.

- Output Shaft

The output shaft from the gearbox transfers high-speed rotation to the generator, crucial for optimal electricity production with minimal energy loss.

- Lubrication System

The lubrication system in a wind energy gearbox is vital for reducing friction, cooling components, and preventing wear and corrosion.

It ensures the smooth operation of gear sets and bearings during extended periods of wind energy generation.

Key Benefits of Wind Energy Gearboxes

Designing wind energy gearboxes with these considerations in mind offers a multitude of benefits, essential for the advancement and efficiency of wind energy systems. These benefits include:

- Enhanced Performance: Optimized material selection and gear ratios contribute to the gearbox's ability to efficiently convert wind energy into electrical power, maximizing the performance of wind turbines.

- Increased Durability: The use of durable materials and designs tailored for reliability extend the operational lifespan of the gearbox, reducing the need for frequent replacements and lowering long-term operational costs.

- Improved Efficiency: By minimizing energy losses through efficient design, wind energy gearboxes ensure that a higher proportion of captured wind energy is converted into usable electricity, enhancing the overall efficiency of wind turbines.

- Reduced Maintenance Needs: Designing for durability and ease of maintenance means that gearboxes are less likely to fail and easier to repair when issues do arise, leading to lower downtime and maintenance costs.

- Environmental Sustainability: Emphasizing environmentally friendly materials and processes in gearbox design reduces the environmental impact of wind turbines, aligning with the renewable energy sector's goal of minimizing carbon footprints.

Design Considerations for Wind Energy Gearboxes

Designing a wind energy gearbox requires comprehensive consideration of various factors to ensure optimal performance under challenging conditions. Here is a consolidated list of key design considerations:

- Material Selection: Choosing materials that offer durability, strength, and resistance to environmental stressors like temperature changes and corrosion, with a preference for advanced alloys and composites for their excellent strength-to-weight ratios.

- Gear Ratio Optimization: Calculating the ideal gear ratio to efficiently convert the rotor's slow rotational speed to the higher speed needed by the generator, using simulations to predict performance across variable wind conditions.

- Efficiency Maximization: Focusing on reducing energy losses by minimizing friction, optimizing gear meshing, and managing heat generation through effective thermal management strategies.

- Durability and Reliability: Ensuring the gearbox can withstand constant operational stresses with materials and designs that facilitate ease of maintenance, incorporating reliability engineering principles to predict lifespan and potential failure modes.

- Noise Reduction: Implementing design strategies to minimize noise output, including the use of noise-dampening materials and designing gear teeth to reduce vibration.

- Environmental Considerations: Taking into account the gearbox's operational impact on the environment, aiming for designs that use environmentally friendly materials and processes, and considering recyclability at the end of the gearbox's service life.

Innovations in Wind Energy Gearbox Technology

The wind energy sector is witnessing a surge in innovative solutions aimed at overcoming traditional gearbox challenges.

These include the development of more robust and efficient gear materials, the integration of smart sensors for real-time monitoring and predictive maintenance, and the exploration of gearbox-less direct drive turbines.

Best Practices for Wind Energy Gearbox Maintenance

- Regular Inspections: Conducting routine checks to identify wear and tear.

- Lubrication: Ensuring proper lubrication to reduce friction and wear.

- Condition Monitoring: Implementing advanced monitoring systems for early detection of potential failures.

- Scheduled Maintenance: Establishing a comprehensive maintenance schedule based on manufacturer recommendations and operational data to preemptively address issues before they escalate.

- Temperature Monitoring: Utilizing temperature sensors to track gearbox operating temperatures, can indicate lubrication effectiveness and potential overheating problems.

- Vibration Analysis: Applying vibration analysis techniques to detect anomalies in gearbox operation that may signify misalignments, imbalances, or bearing failures.

- Oil Analysis: Periodically analyze gearbox oil for contaminants and metal particles, which can reveal internal wear and the health of the gearbox.

The Critical Role of Wind Energy Gearbox Manufacturers in Advancing Renewable Energy

Wind energy gearbox manufacturers are indispensable to the renewable energy sector, embodying the innovation and engineering prowess required to harness wind power effectively.

These manufacturers specialize in producing the heart of the wind turbine—the gearbox—which plays a crucial role in converting kinetic wind energy into usable electrical power.

Wind energy gearbox manufacturers prioritize precision engineering to boost turbine efficiency, creating reliable and affordable wind energy solutions. Their dedication to advancing gearbox technology enhances overall turbine performance, crucial for global sustainability and renewable energy goals.

The Future of Wind Energy Gearboxes

The demand for renewable energy is increasing, driving innovation in wind energy gearboxes to improve efficiency and performance. Research efforts are shaping the future of these critical components.

- Material Science and Engineering Breakthroughs

A key focus is on new materials for wind turbines that are strong, durable, and resistant to harsh conditions. Advanced alloys and composites aim to make gearboxes lighter and longer-lasting, boosting performance and efficiency.

- Revolutionary Design Innovations

Engineers are revising wind energy gearbox designs to be more compact, efficient, and less complex, reducing mechanical failures and costs. Direct-drive systems are being explored to increase efficiency and decrease maintenance needs by eliminating the gearbox.

- Operational Efficiency Improvements

Integrating smart technologies and IoT into gearbox systems improves monitoring and maintenance, reducing downtime and extending wind turbine lifespan. Computational models predict performance and optimize efficiency and reliability.

- Cost-Reduction Strategies

Future wind energy gearbox development focuses on cost reduction by improving efficiency and longevity. This makes wind energy production more competitive and accessible globally.

- Environmental Impact Considerations

The environmental impact of wind energy gearboxes is being examined, with a focus on creating more recyclable designs to reduce their carbon footprint and align with renewable energy goals.

FAQs on Wind Energy Gearboxes

What is a wind energy gearbox?

A wind energy gearbox is a critical component of a wind turbine that increases the rotational speed of the turbine's rotor blades to a level suitable for electricity generation by the generator. It plays a pivotal role in the efficient conversion of kinetic wind energy into electrical energy.

How do wind energy gearboxes improve wind turbine efficiency?

Wind energy gearboxes improve turbine efficiency by optimizing the rotational speed of the turbine blades to match the operational speed required by the generator. This optimization ensures that the maximum amount of kinetic energy from the wind is converted into usable electrical energy, minimizing energy loss.

What are the main components of a wind energy gearbox?

The main components include the input shaft, which connects to the rotor blades; gear sets, which step up the rotational speed; bearings, which ensure smooth operation of the gears and shafts; and the output shaft, which transfers the increased rotational speed to the generator.

How long do wind energy gearboxes last?

The lifespan of a wind energy gearbox can vary based on its design, materials, and operating conditions. However, with proper maintenance and monitoring, a gearbox can last between 20 to 25 years, which aligns with the average operational lifespan of a wind turbine.

Can wind energy gearboxes be repaired or replaced?

Yes, wind energy gearboxes can be repaired or replaced if they fail or when their performance significantly degrades. Advances in monitoring and diagnostic technologies have improved the ability to predict and prevent failures, reducing downtime and maintenance costs.

Are there alternatives to traditional wind energy gearboxes?

Yes, one alternative is the direct-drive system, which eliminates the need for a gearbox by connecting the rotor directly to the generator. Although these systems can be more reliable and require less maintenance, they are often heavier and more expensive, making them less common in current wind turbine designs.

How are wind energy gearboxes being improved?

Improvements in wind energy gearboxes focus on material advancements, innovative design approaches for increased durability and efficiency, integration of smart technologies for predictive maintenance, and strategies to reduce manufacturing and operational costs. Continuous research and development efforts aim to make gearboxes more reliable and cost-effective.

What role do environmental considerations play in the design of wind energy gearboxes?

Environmental considerations play a significant role in the design and operation of wind energy gearboxes. This includes the use of environmentally friendly materials, designing for recyclability, and minimizing the gearbox's environmental impact throughout its lifecycle to support the overall sustainability goals of wind energy production.

Wind Energy Gearbox Conclusion

The wind energy gearbox is a cornerstone of wind turbine technology, essential for the effective conversion of wind energy into electricity.

Through understanding its operation, challenges, and the latest advancements, we can appreciate the critical role it plays in the global transition toward renewable energy.

As technology progresses, the wind energy gearbox will continue to evolve, offering new opportunities to enhance the efficiency and reliability of wind energy production.